Paint Cure Oven

Paint Cure Oven: Everything You Need to Know Before Buying

If you work in finishing—whether you're applying powder coating, liquid paint, or specialized coatings—you know that the application is only half the battle. The true magic happens during the curing process. Without proper curing, even the most expensive paint job will fail, chipping, cracking, or simply not holding up to daily wear and tear.

That's where the unsung hero of the finishing line steps in: the Paint Cure Oven. Choosing the right oven is one of the most critical investments you'll make for quality control and efficiency. But what exactly should you look for? And how do you ensure you get the perfect cure every time?

We're here to walk you through the specifics. Consider this your complete guide to understanding, selecting, and optimizing your industrial paint cure oven.

What Exactly is a Paint Cure Oven? (The Basics)

At its core, a paint cure oven is a controlled heating chamber designed to facilitate the chemical cross-linking necessary for paint and powder coatings to harden fully. This isn't just about drying; it's a chemical reaction.

When you apply a coating, it exists in a relatively soft state. To achieve the final durable properties—such as corrosion resistance, impact strength, and aesthetic quality—the coating must be exposed to specific temperatures for a set duration. This process is often called baking or thermal curing.

A high-quality Paint Cure Oven ensures that this temperature is maintained uniformly across all surfaces of the part, preventing issues like under-curing (which leads to poor adhesion) or over-curing (which can cause brittleness or discoloration).

The Science Behind the Cure: Convection vs. Infrared

When looking into purchasing a Paint Cure Oven, you will quickly encounter two primary methods of heat transfer. Understanding the difference between convection and infrared curing is crucial, as each suits different types of parts and production volumes.

Convection Paint Cure Ovens

Convection ovens are the traditional workhorse of the industry. They heat the air inside the chamber, and that heated air is then circulated using fans. This circulation system transfers thermal energy to the surface of the parts.

These ovens are excellent for handling complex geometries, large parts, and thick materials because the heated air eventually envelops the entire surface, ensuring a thorough soak.

Key features of convection ovens include:

- Excellent for parts with varying thicknesses or intricate shapes.

- Requires longer cure times compared to infrared, as the parts must heat up gradually.

- Offers exceptional temperature uniformity within the curing space.

- Used widely for both powder coating and liquid paint systems.

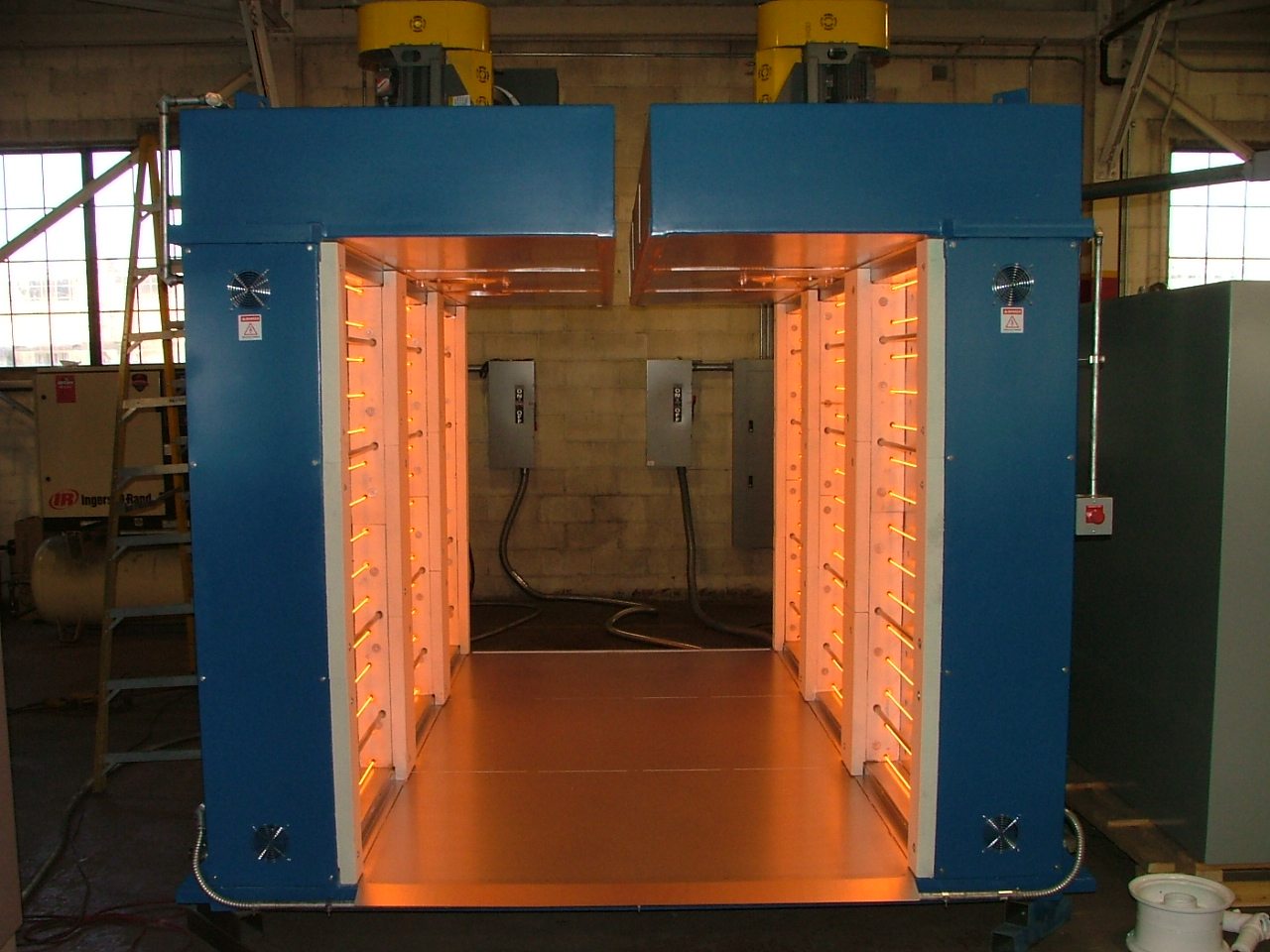

Infrared Paint Cure Ovens

Infrared (IR) ovens operate differently; they don't rely on heating the air. Instead, they emit electromagnetic radiation which is directly absorbed by the surface of the part, instantly generating heat from the outside in.

Think of it like standing in sunlight—you feel the heat instantly, regardless of the surrounding air temperature. This method is incredibly fast and highly energy-efficient for specific applications.

However, IR ovens work best on parts that are relatively flat or have simple geometries. If a part has shadows or complex curves, the IR waves may not hit those areas directly, leading to uneven curing.

Benefits often cited by users of IR Paint Cure Ovens:

- Significantly faster ramp-up and cure times.

- Lower overall energy consumption due to heating only the material, not the surrounding atmosphere.

- Ideal for production lines requiring high throughput of uniform parts.

Key Factors When Selecting Your Paint Cure Oven

Choosing the right industrial Paint Cure Oven is a significant decision that impacts your operational costs and product quality for years to come. Here are the most important considerations you must evaluate before making a purchase.

Size and Capacity Considerations

First and foremost, the oven must physically accommodate the largest parts you plan to process. But size isn't just about width and height; it's about throughput—how many parts can you cure per hour or per day?

Ensure that the oven's capacity aligns with your desired production volume. Don't buy an oven that meets your current needs if you anticipate rapid growth in the near future.

Batch Ovens vs. Conveyor Ovens

This distinction directly relates to production flow. Understanding your production needs helps determine which type of Paint Cure Oven structure is best.

Batch Ovens are large stationary chambers. Parts are loaded, the oven is sealed, the cycle runs, and then the parts are unloaded. They are flexible for varying part sizes and are typically suited for lower-volume operations, custom work, or large, bulky components.

Conveyor Ovens integrate directly into a continuous finishing line. Parts move through the oven on a conveyor belt, heating zone by zone. These are essential for high-volume manufacturing where speed and repeatability are paramount.

Temperature Uniformity and Control

Temperature variation is the enemy of a perfect finish. Even a deviation of 10°F (5.5°C) can be enough to significantly compromise the durability and color consistency of a coating.

When investigating a new Paint Cure Oven, ask the manufacturer about the temperature uniformity standard (TUS). High-quality ovens are often certified to maintain temperatures within a very tight tolerance across the entire heated zone, ensuring every square inch of every part is cured correctly.

Modern ovens should also feature sophisticated programmable logic controllers (PLCs) that allow for precise ramp-up rates, soak times, and temperature logging. This data is critical for meeting quality assurance requirements and optimizing complex cure profiles.

Maintaining Your Paint Cure Oven for Peak Performance

Once you have invested in a quality oven, regular maintenance is key to protecting that investment. Consistent maintenance ensures energy efficiency and, more importantly, consistent coating quality.

Maintenance steps often include:

- Checking and calibrating temperature sensors (thermocouples) regularly.

- Cleaning internal ductwork and exhaust systems to maintain airflow efficiency.

- Inspecting the insulation and seals to prevent heat loss, which increases energy costs.

- Testing the recirculation fan motors to ensure proper air movement throughout the chamber.

Remember, downtime caused by a malfunctioning Paint Cure Oven halts your entire production line. A proactive maintenance schedule minimizes that risk significantly.

Conclusion: The Value of a Quality Paint Cure Oven

Selecting the right equipment goes far beyond just buying a box that gets hot. A well-chosen Paint Cure Oven is a guarantee of quality, efficiency, and durability for your finished products.

Whether you opt for the speed of infrared or the thoroughness of convection, focus on capacity, uniformity, and control. By carefully considering your operational flow and the nature of the parts you coat, you can select an oven that transforms your finishing line from standard to exceptional. Investing in high-quality curing equipment is truly investing in the integrity of your product.

Frequently Asked Questions (FAQ) About Paint Cure Ovens

- What is the typical operating temperature for a powder coating cure oven?

- The typical curing temperature for standard powder coatings ranges between 350°F (177°C) and 400°F (204°C). However, low-cure powders can activate at temperatures as low as 250°F (120°C).

- How does a Paint Cure Oven differ from a standard drying oven?

- A standard drying oven is primarily used to evaporate solvents or moisture. A Paint Cure Oven, especially for thermoset coatings like powder, facilitates a chemical reaction (cross-linking) at high temperatures to fundamentally change the molecular structure of the coating, making it hard and durable.

- Can I use a batch oven for high-volume production?

- While you can use a batch oven for high volumes, it is generally less efficient than a continuous conveyor system. Batch ovens require cooling and reheating cycles, which increases labor time and energy consumption per part compared to a continuously moving line.

- Is a gas or electric Paint Cure Oven better?

- The choice depends heavily on location, utility costs, and required temperatures. Gas (Natural Gas or Propane) ovens typically heat up faster and may be cheaper to operate in areas with low gas prices. Electric ovens offer highly precise temperature control and are often favored when gas infrastructure is unavailable or if precision is the absolute top priority.

Paint Cure Oven

Paint Cure Oven Wallpapers

Collection of paint cure oven wallpapers for your desktop and mobile devices.

Dynamic Paint Cure Oven Photo Photography

Immerse yourself in the stunning details of this beautiful paint cure oven wallpaper, designed for a captivating visual experience.

Amazing Paint Cure Oven Photo Photography

Discover an amazing paint cure oven background image, ideal for personalizing your devices with vibrant colors and intricate designs.

Vivid Paint Cure Oven Background in HD

Discover an amazing paint cure oven background image, ideal for personalizing your devices with vibrant colors and intricate designs.

Vibrant Paint Cure Oven Artwork Nature

Experience the crisp clarity of this stunning paint cure oven image, available in high resolution for all your screens.

Stunning Paint Cure Oven Image Collection

This gorgeous paint cure oven photo offers a breathtaking view, making it a perfect choice for your next wallpaper.

Detailed Paint Cure Oven Background for Desktop

Discover an amazing paint cure oven background image, ideal for personalizing your devices with vibrant colors and intricate designs.

Mesmerizing Paint Cure Oven Image Nature

Transform your screen with this vivid paint cure oven artwork, a true masterpiece of digital design.

Lush Paint Cure Oven Image Photography

A captivating paint cure oven scene that brings tranquility and beauty to any device.

Crisp Paint Cure Oven Moment in HD

Find inspiration with this unique paint cure oven illustration, crafted to provide a fresh look for your background.

Amazing Paint Cure Oven Wallpaper Illustration

Experience the crisp clarity of this stunning paint cure oven image, available in high resolution for all your screens.

Gorgeous Paint Cure Oven Picture in 4K

A captivating paint cure oven scene that brings tranquility and beauty to any device.

Exquisite Paint Cure Oven Landscape for Your Screen

Immerse yourself in the stunning details of this beautiful paint cure oven wallpaper, designed for a captivating visual experience.

Spectacular Paint Cure Oven Artwork Digital Art

This gorgeous paint cure oven photo offers a breathtaking view, making it a perfect choice for your next wallpaper.

Gorgeous Paint Cure Oven Artwork for Your Screen

A captivating paint cure oven scene that brings tranquility and beauty to any device.

Beautiful Paint Cure Oven Picture Concept

Explore this high-quality paint cure oven image, perfect for enhancing your desktop or mobile wallpaper.

Beautiful Paint Cure Oven Image for Desktop

Explore this high-quality paint cure oven image, perfect for enhancing your desktop or mobile wallpaper.

Dynamic Paint Cure Oven Background for Desktop

A captivating paint cure oven scene that brings tranquility and beauty to any device.

Stunning Paint Cure Oven Capture Art

Find inspiration with this unique paint cure oven illustration, crafted to provide a fresh look for your background.

Breathtaking Paint Cure Oven Moment Photography

Explore this high-quality paint cure oven image, perfect for enhancing your desktop or mobile wallpaper.

Mesmerizing Paint Cure Oven Artwork Photography

Experience the crisp clarity of this stunning paint cure oven image, available in high resolution for all your screens.

Download these paint cure oven wallpapers for free and use them on your desktop or mobile devices.